"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

10/14/2016 at 14:55 ē Filed to: None

0

0

27

27

"OPPOsaurus WRX" (opposaurus)

"OPPOsaurus WRX" (opposaurus)

10/14/2016 at 14:55 ē Filed to: None |  0 0

|  27 27 |

how would you go about insulating a shipping container?

If they are 8' wide,you instantly lose probably 2" each side with the corrugated walls which brings you to 7'8". The most common insulating material iím familiar with is closed cell poly-sumthin-shit which has an R value of 7.5 per inch. So 3" of that gets you 21.5. then sheet rock, so that puts you around 7' clear. All options are good options.

crowmolly

> OPPOsaurus WRX

crowmolly

> OPPOsaurus WRX

10/14/2016 at 14:57 |

|

Iíd spray in between the corrugation before putting up foam.

Any chance of adding insulation on the outside?

Michael

> OPPOsaurus WRX

Michael

> OPPOsaurus WRX

10/14/2016 at 14:57 |

|

http://containertech.com/about-containers/insulating-a-shipping-container/

For Sweden

> OPPOsaurus WRX

For Sweden

> OPPOsaurus WRX

10/14/2016 at 14:58 |

|

Frame the inside and use blow-in insulation

Michael

> Michael

Michael

> Michael

10/14/2016 at 14:59 |

|

Spray foam seems to give you the most interior room but has the highest cost

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> For Sweden

JawzX2, Boost Addict. 1.6t, 2.7tt, 4.2t

> For Sweden

10/14/2016 at 14:59 |

|

My thought exactly, use that corrugation to hold your insulator.

Takuro Spirit

> OPPOsaurus WRX

Takuro Spirit

> OPPOsaurus WRX

10/14/2016 at 14:59 |

|

Depends on what youíre using it for.

Moves-Like-Senna

> OPPOsaurus WRX

Moves-Like-Senna

> OPPOsaurus WRX

10/14/2016 at 14:59 |

|

From experience, Iíve used closed cell spray foam and itís done a fantastic job.

Demon-Xanth knows how to operate a street.

> For Sweden

Demon-Xanth knows how to operate a street.

> For Sweden

10/14/2016 at 15:00 |

|

Assuming itís going to be static, there you go. If it is going to move around youíll want to use an expanding foam that turns solid otherwise all the insulation will pack down in the bottom.

and 100 more

> OPPOsaurus WRX

and 100 more

> OPPOsaurus WRX

10/14/2016 at 15:00 |

|

Iíve seen blown polyfill done behind the sheetrock before, but I donít think that insulates too well. Also, spray-on foam (similar to Fix-a-flat), which turns rigid (like fix-a-flat), but supposedly insulates pretty well.

Other than that, I think youíre down to expanded polystyrene (styrofoam) sheets.

(I donít know much about shipping container insulation, aside from what Iíve picked up during my own research.)

OPPOsaurus WRX

> For Sweden

OPPOsaurus WRX

> For Sweden

10/14/2016 at 15:02 |

|

blow in has an R value of 4 per inch or less.

OPPOsaurus WRX

> Demon-Xanth knows how to operate a street.

OPPOsaurus WRX

> Demon-Xanth knows how to operate a street.

10/14/2016 at 15:02 |

|

thats the closed cell stuff @ 7.5 per inch, blow in is 3-4 per inch

CB

> OPPOsaurus WRX

CB

> OPPOsaurus WRX

10/14/2016 at 15:03 |

|

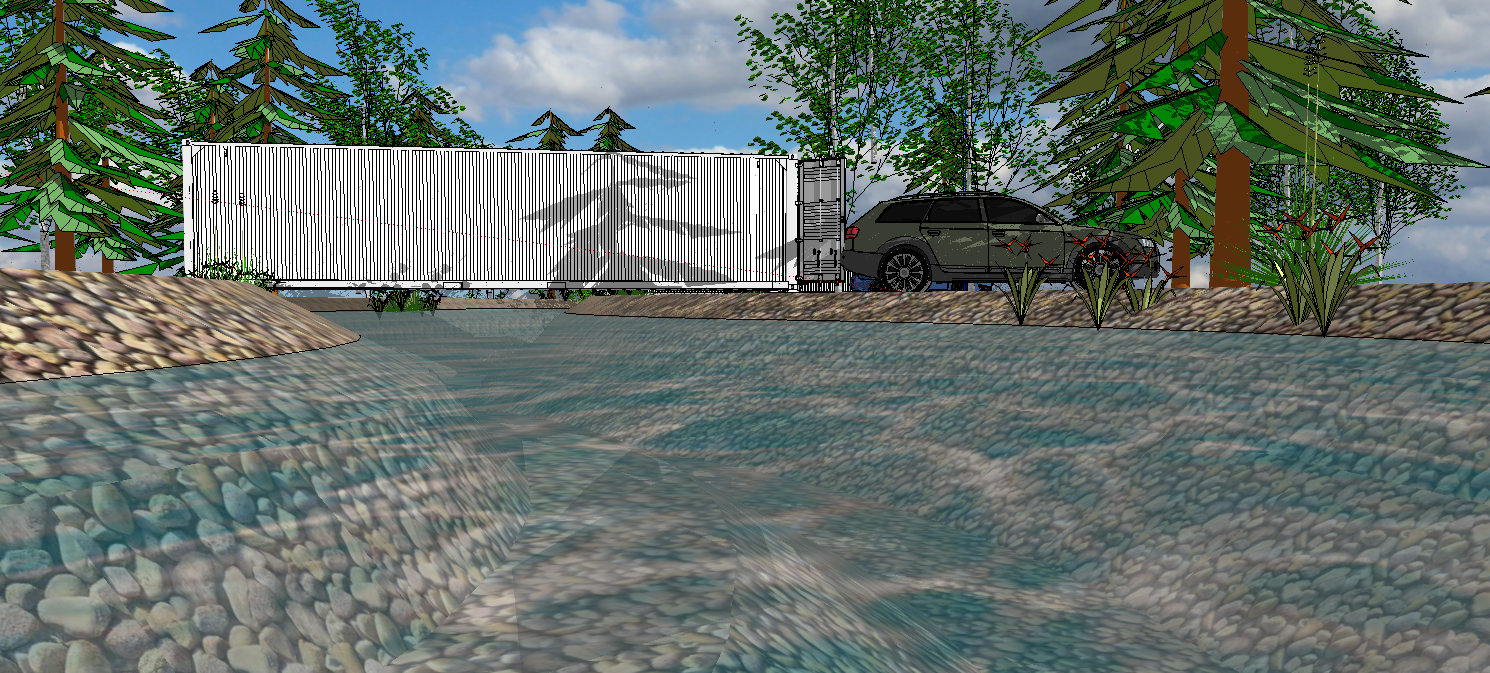

Iíd love to use four* or so shipping crates as a house. Two on the bottom for kitchen/dining/living room, two on top for a bedroom and office, perpendicular to each other, put a deck on top of the bottom ones, do a mostly open concept design, could be cool.

*may need more than four

OPPOsaurus WRX

> crowmolly

OPPOsaurus WRX

> crowmolly

10/14/2016 at 15:04 |

|

nothing on the outside. the corrugated steel is a nice exterior weather barrier, so any insulation on the outside would have to then get another layer of siding or something

OPPOsaurus WRX

> Moves-Like-Senna

OPPOsaurus WRX

> Moves-Like-Senna

10/14/2016 at 15:05 |

|

thats the best I can come up with just from my house building experience. I was hoping there would be something with a better R value but it doesn;t seem like it.

OPPOsaurus WRX

> Takuro Spirit

OPPOsaurus WRX

> Takuro Spirit

10/14/2016 at 15:05 |

|

insulating a metal container for a habitability space in a cold enviroment

Takuro Spirit

> OPPOsaurus WRX

Takuro Spirit

> OPPOsaurus WRX

10/14/2016 at 15:07 |

|

Keeping cold out and warmth from some sort of heating source IN?

Moves-Like-Senna

> OPPOsaurus WRX

Moves-Like-Senna

> OPPOsaurus WRX

10/14/2016 at 15:10 |

|

I know the R value isnít the greatest but remember youíre trying to insulate something that isnít designed to retain heat and is built out of thin metal.

If you told me as a child that bats of insolation would turn into spray foam Iíd have called you mad! haha It astonishes me just how far weíve come with technology.

OPPOsaurus WRX

> Takuro Spirit

OPPOsaurus WRX

> Takuro Spirit

10/14/2016 at 15:12 |

|

thats the plan

hedbutter

> crowmolly

hedbutter

> crowmolly

10/14/2016 at 15:21 |

|

I know nothing about this, but maybe do a 1x2 frame, spray insulation between frame and metal, and then 1 sheet of insulation? Either way, id spray insulate between the framing for drywall and the container.

If only EssExTee could be so grossly incandescent

> OPPOsaurus WRX

If only EssExTee could be so grossly incandescent

> OPPOsaurus WRX

10/14/2016 at 15:29 |

|

Check this site out: http://seacontainercabin.blogspot.com/p/framing.html

You could also embed one side in a hill, thatíll provide natural insulation and minimize space loss.

Roundbadge

> OPPOsaurus WRX

Roundbadge

> OPPOsaurus WRX

10/14/2016 at 15:43 |

|

Iíd think the poly blow-in insulation is the answer here...as you say, definitely not the cellulose stuff. Iím talking about the kind that they spray on and then use a screed to level off so they can drywall over it.

Iíve considered doing the same in my current home. It was built in Ď27 and was insulated with cellulose before we moved in. As the house is a balloon-framed 2.5-story, itís a fair bet that cellulose is settling more than it should. Unfortunately, thereís more pressing issues to deal with at the moment.

Takuro Spirit

> OPPOsaurus WRX

Takuro Spirit

> OPPOsaurus WRX

10/14/2016 at 15:44 |

|

Maybe some automotive grade reflective stick on carpet insulation like Dynamat but better insulation qualities?

OPPOsaurus WRX

> If only EssExTee could be so grossly incandescent

OPPOsaurus WRX

> If only EssExTee could be so grossly incandescent

10/14/2016 at 15:46 |

|

thats a good find.

i had thought of sheltering in the hill but iíd also like to either span a steam with it or extend it off a slope with a couple steel legs down to the ground

Chinny Raccoon

> OPPOsaurus WRX

Chinny Raccoon

> OPPOsaurus WRX

10/14/2016 at 15:53 |

|

The one I have has a thin layer of spray on foam on the roof. Works to stop condensation but thatís about it.

If I was doing this Iíd use the corrugations to put support timbers in then sheet over with Kingspan sheet insulation (not sure what the local equivalent is). Either use the drywall faced stuff or screw drywall sheet hrough to the wood in the corrugations.

If only EssExTee could be so grossly incandescent

> OPPOsaurus WRX

If only EssExTee could be so grossly incandescent

> OPPOsaurus WRX

10/14/2016 at 15:58 |

|

http://www.containerhomeplans.org/

gogmorgo - rowing gears in a Grand Cherokee

> OPPOsaurus WRX

gogmorgo - rowing gears in a Grand Cherokee

> OPPOsaurus WRX

10/15/2016 at 13:54 |

|

I would suggest something other than spanning a stream. In my experience, streams have a tendency to get a LOT bigger, and shipping containers have a tendency to float (at least for a little while). Those two things donít go together very well, IMO.

Iíd be perfectly down with living in a container completely buried in a hill, though. Maybe even connect a few together and build a tunnel complex. Make your own little hobbit hole.

OPPOsaurus WRX

> gogmorgo - rowing gears in a Grand Cherokee

OPPOsaurus WRX

> gogmorgo - rowing gears in a Grand Cherokee

10/15/2016 at 14:38 |

|

Meh Iíll make sure to add an anchor. Honestly tho, I would expect the†conservation department would never let that pass. Itíd just a start to get the concept in motion. Think of it like a concept car, flashy at the start and ends up just another car.